Environmental sustainability is deeply embedded into our Company’s culture. As a purpose-driven Company, we strive to improve the lives of our people and the communities residing in areas where we operate by manufacturing more eco-friendly products.

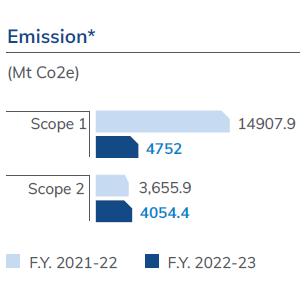

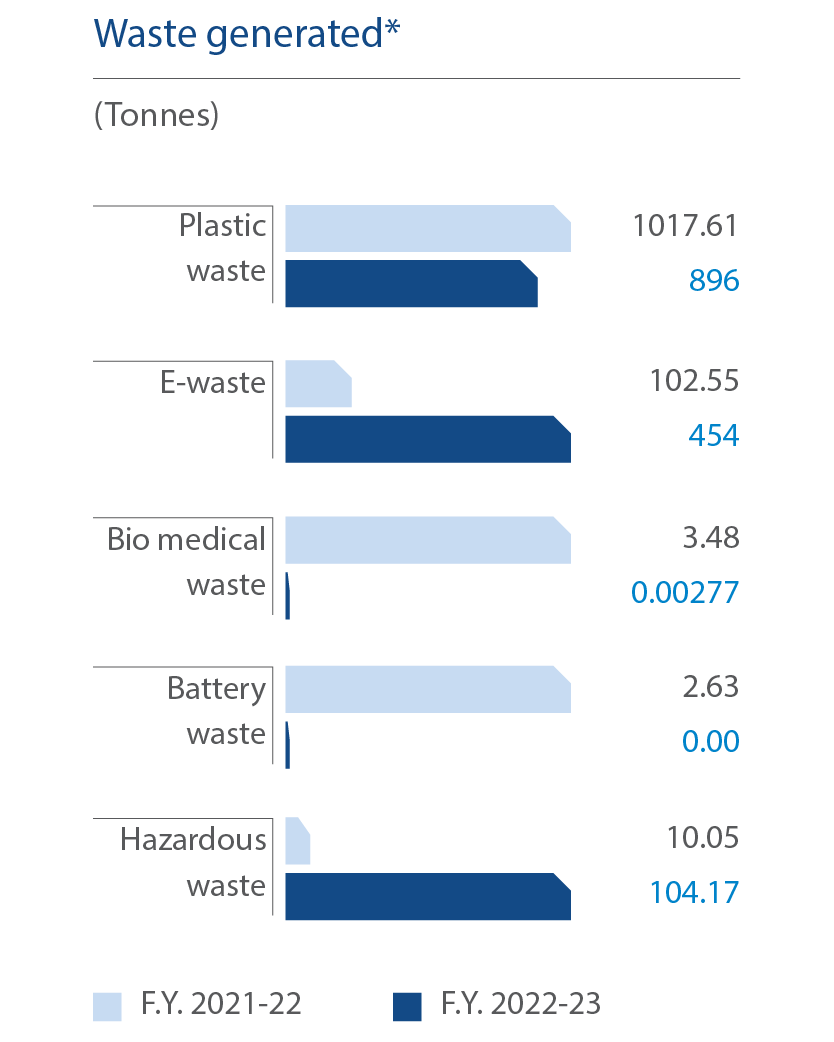

We are making conscious efforts to limit our environmental impact by committing to low resource utilisation and producing innovative products. Our environmental initiatives are aimed at optimising resource utilisation and reducing climate-related threats by developing an energy-efficient portfolio. Our efforts in energy management, waste management, water conservation and emissions reduction help us operate sustainably.

Energy management

As a manufacturing enterprise, energy consumption accounts for a significant portion of our Company’s carbon emission. Therefore, improving energy efficiency is vital. We have devised a performance-based energy management plan to limit our energy consumption, integrate renewable energy sources and embrace energy-efficient practices.

Developing energy efficient products

We leverage our innovation to design products that serve the needs of our consumers. With rising customer awareness and the government’s emphasis on energy regulation, our innovation is focused on producing energy-efficient products. We have undertaken several initiatives to improve energy efficiency, decrease emissions and optimise the use of natural resources. As members of the BEE star ratings, we try to develop energy-saving products that allow our consumers to live more sustainably. We are always working towards minimising GHG emissions across our operations.

Download Full Report