Project Unnati

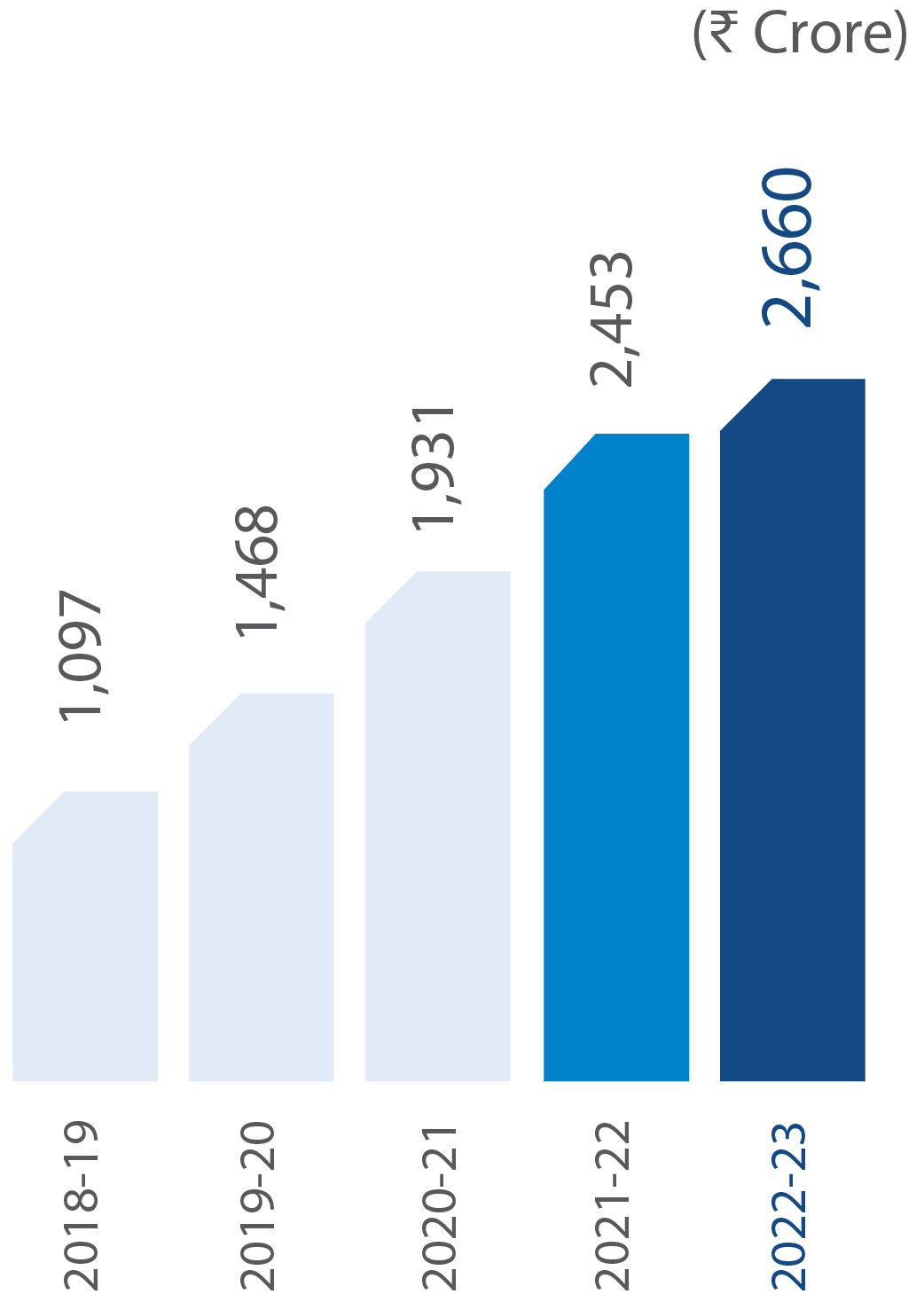

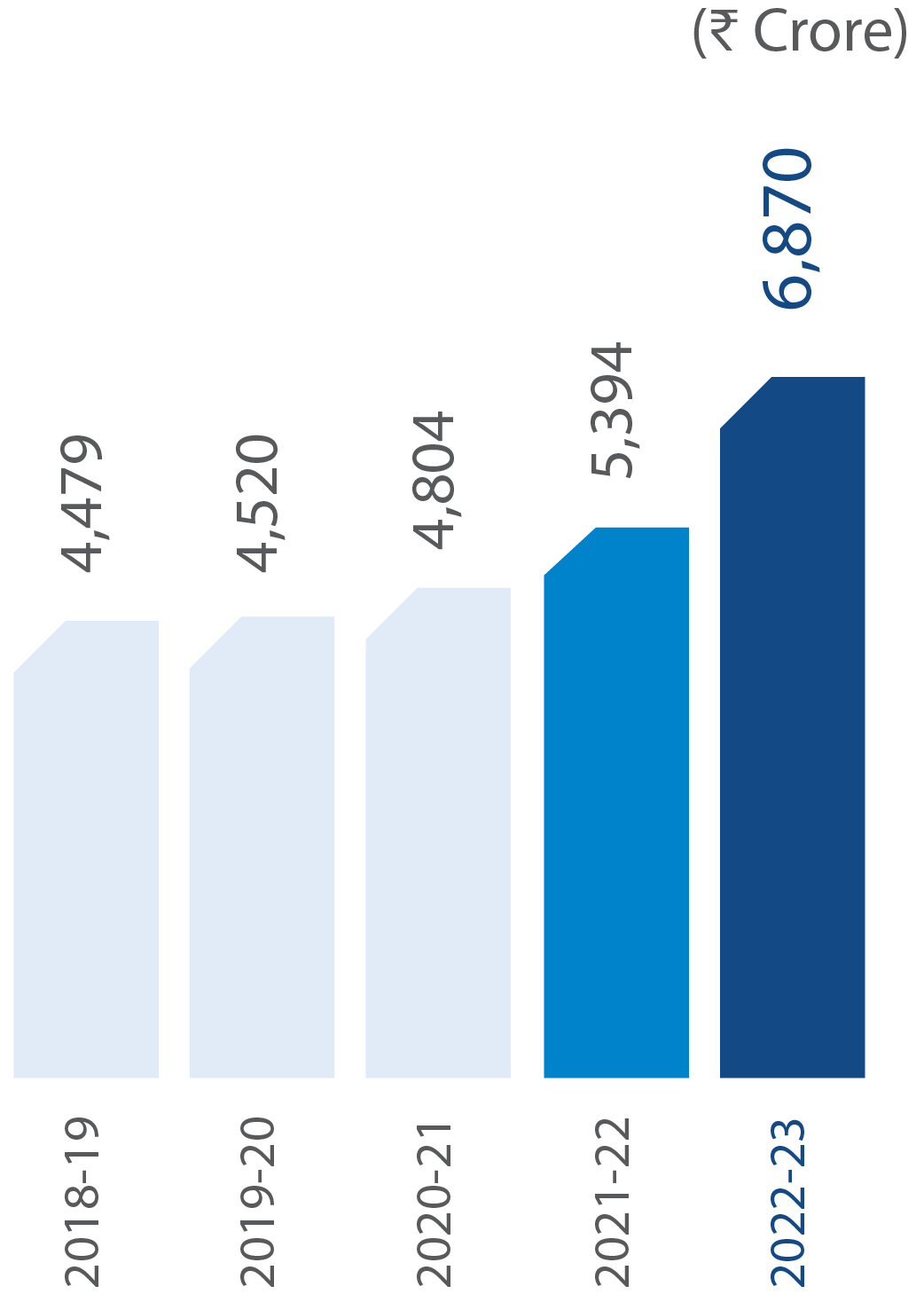

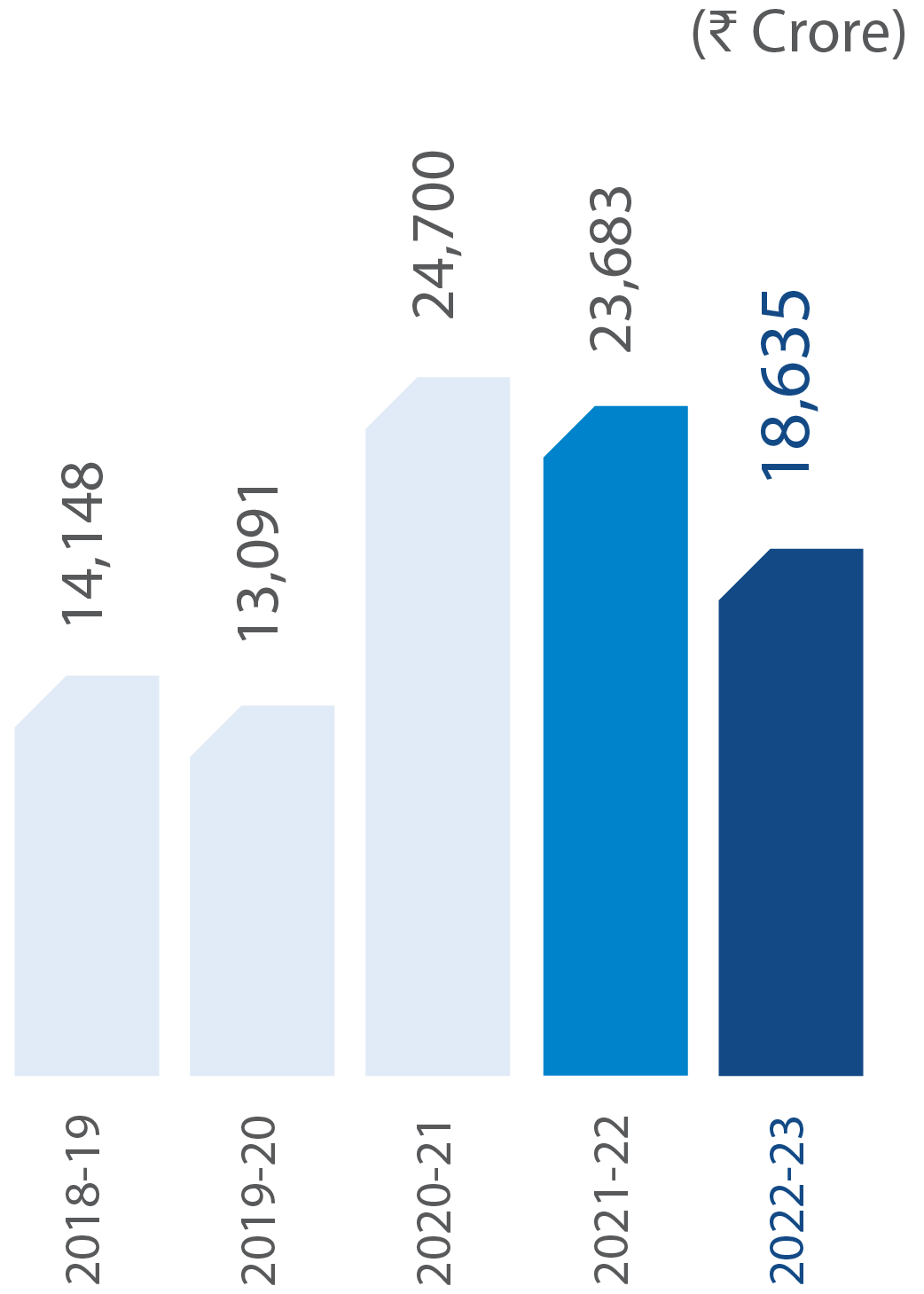

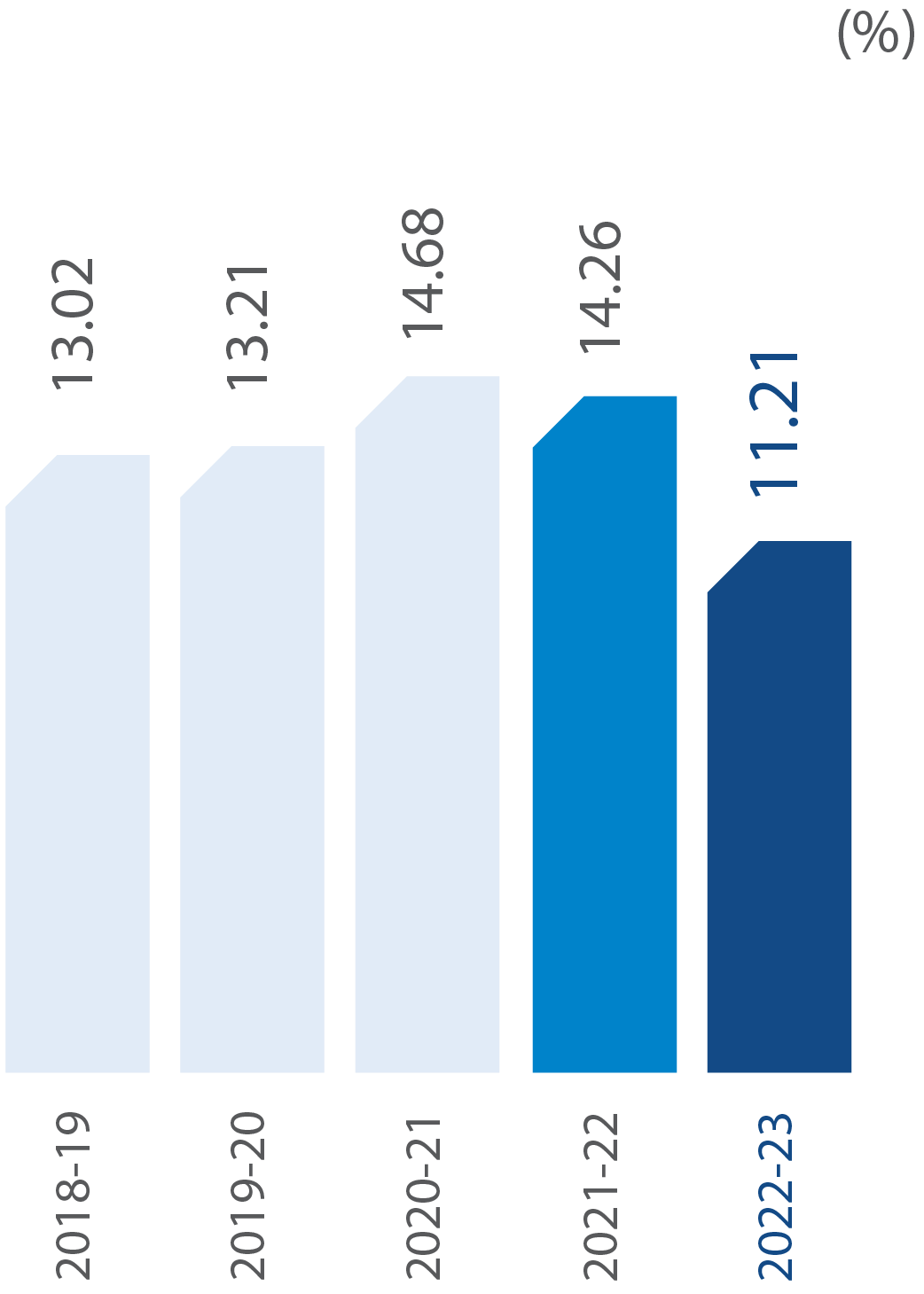

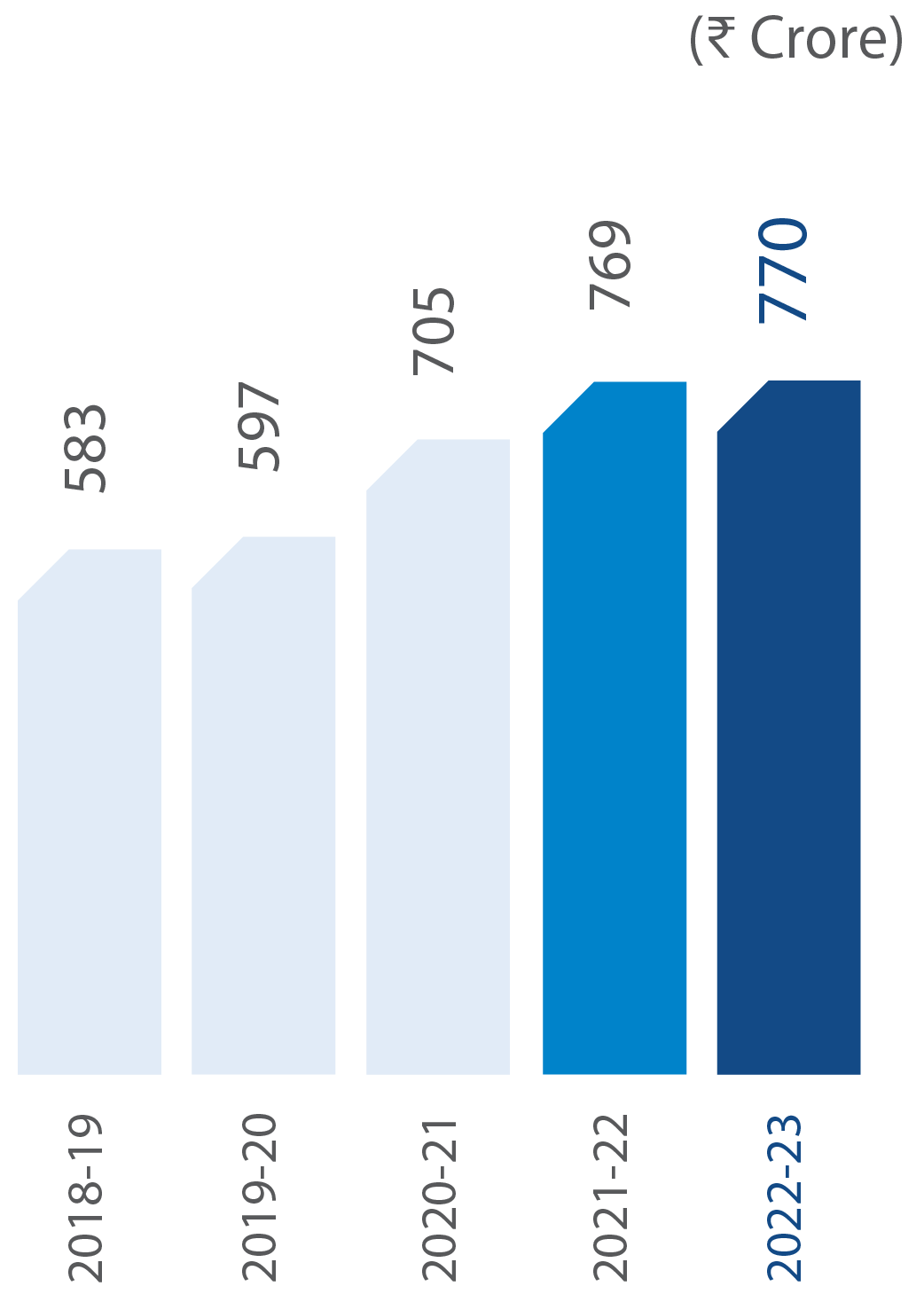

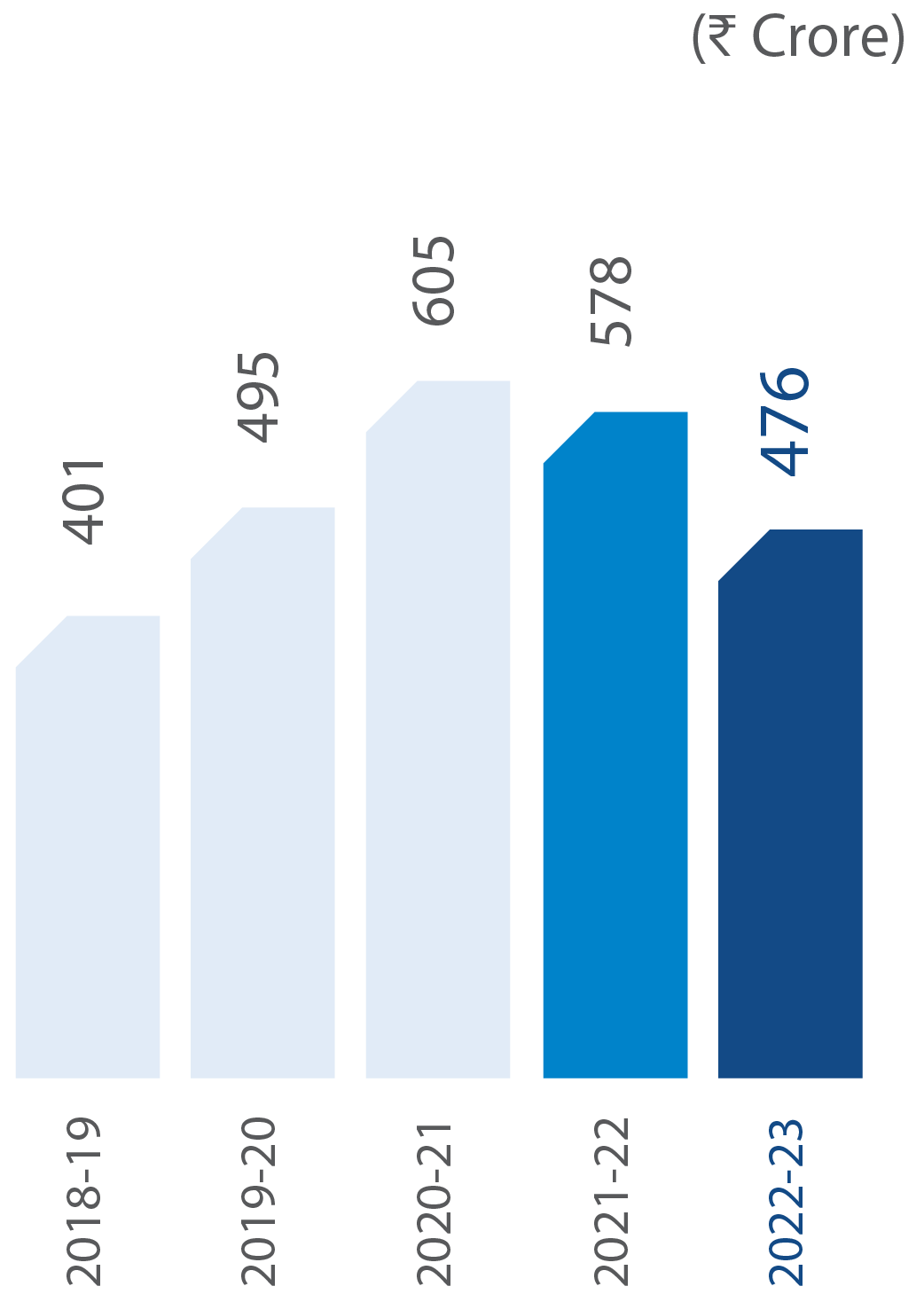

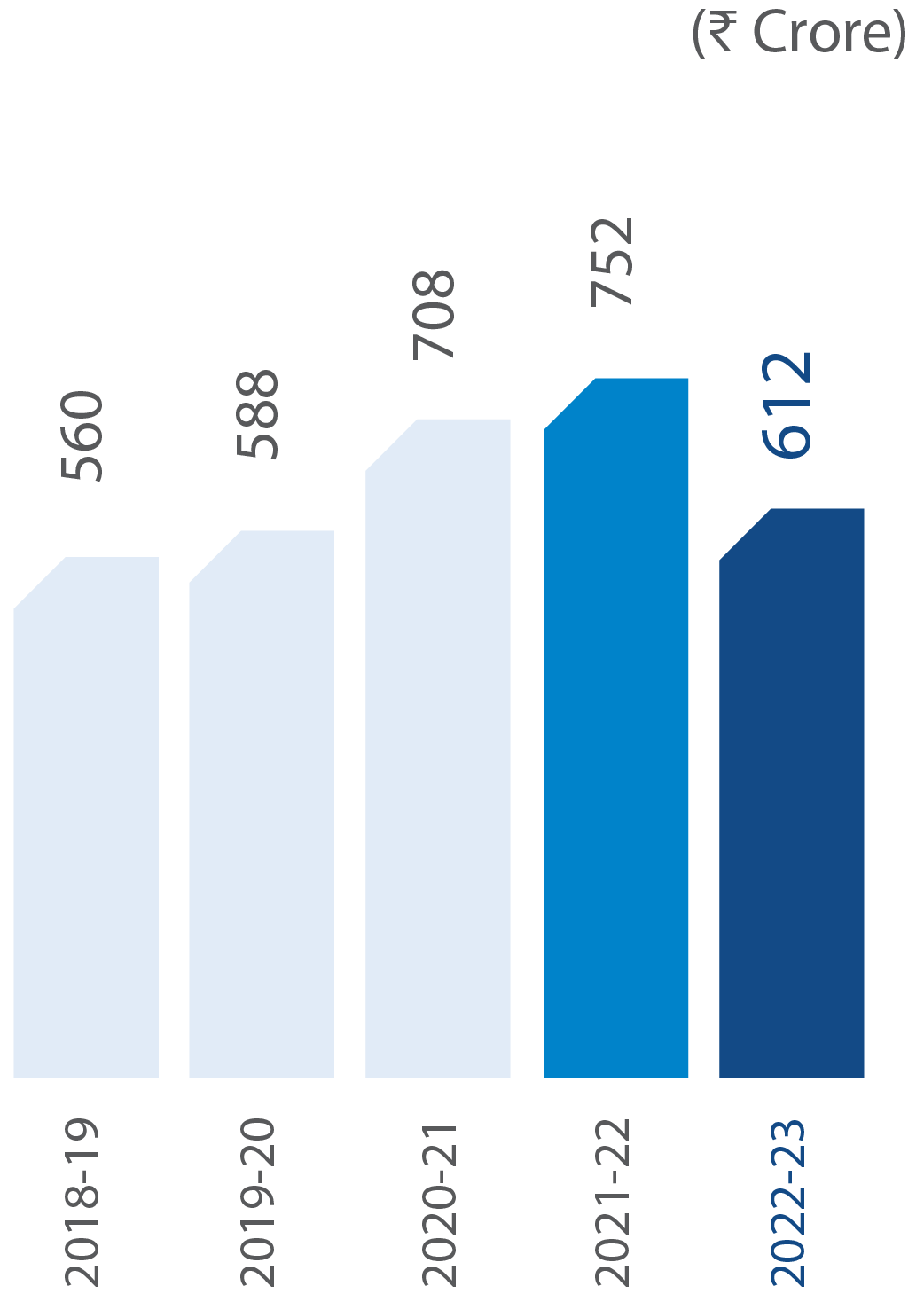

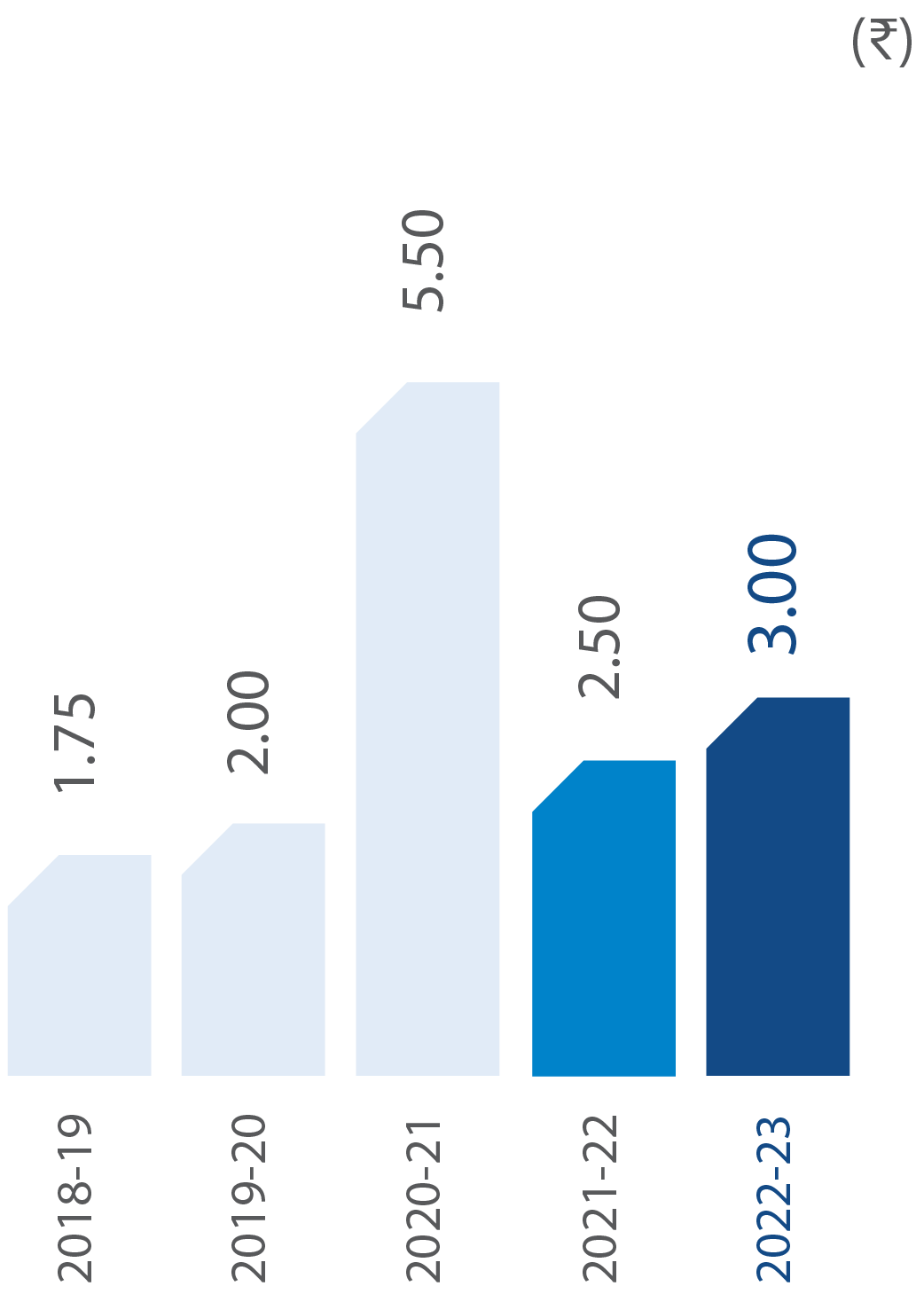

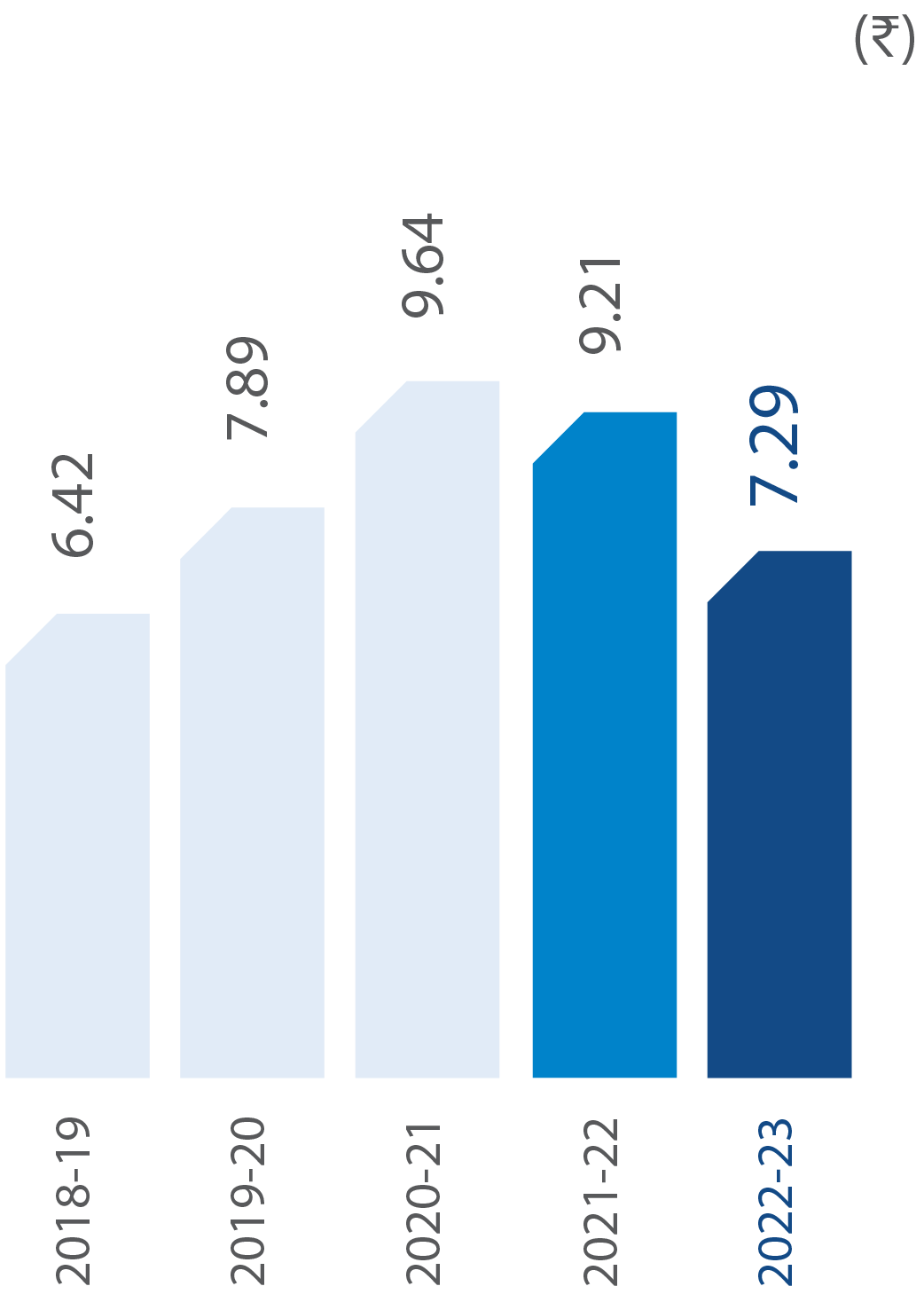

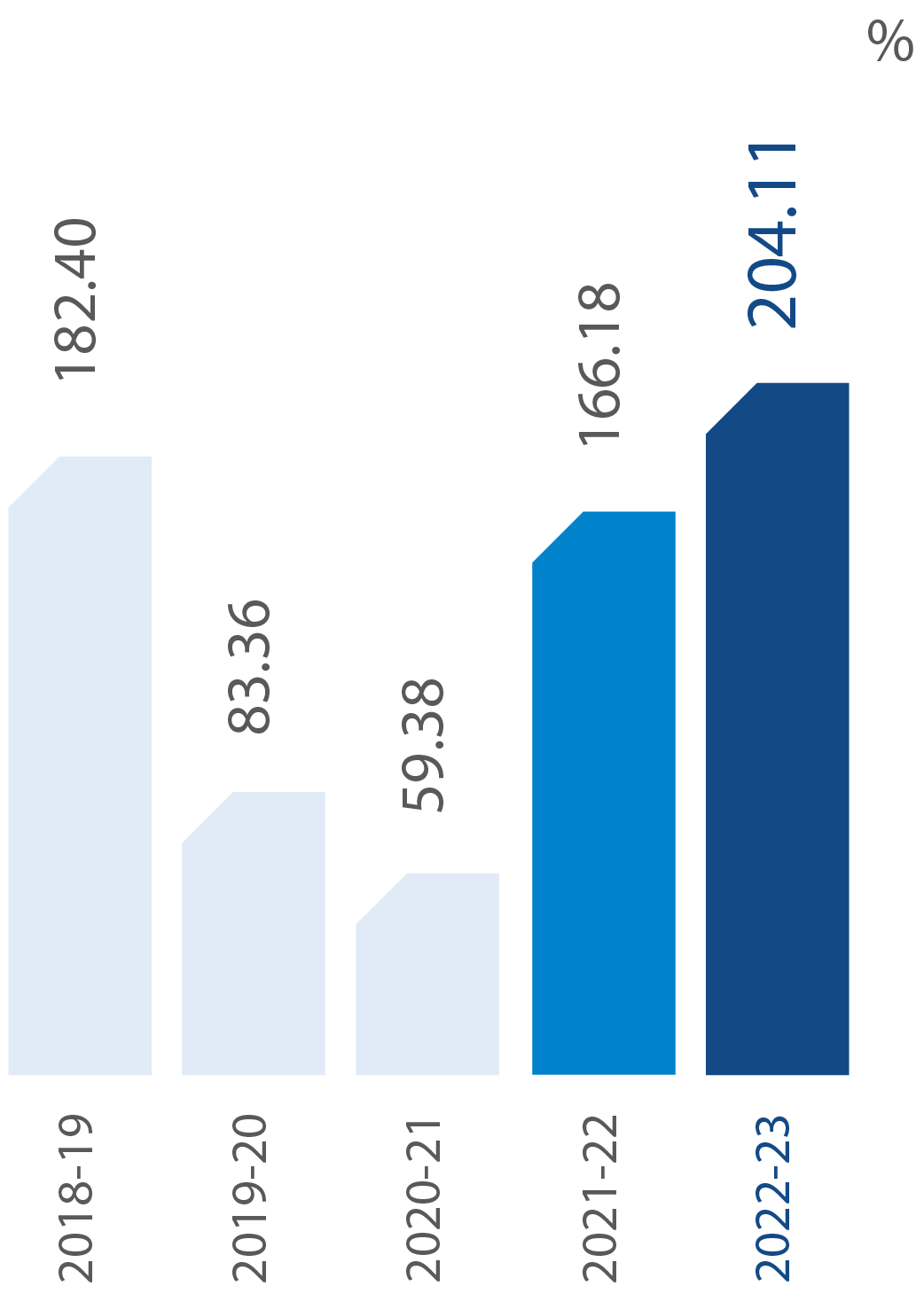

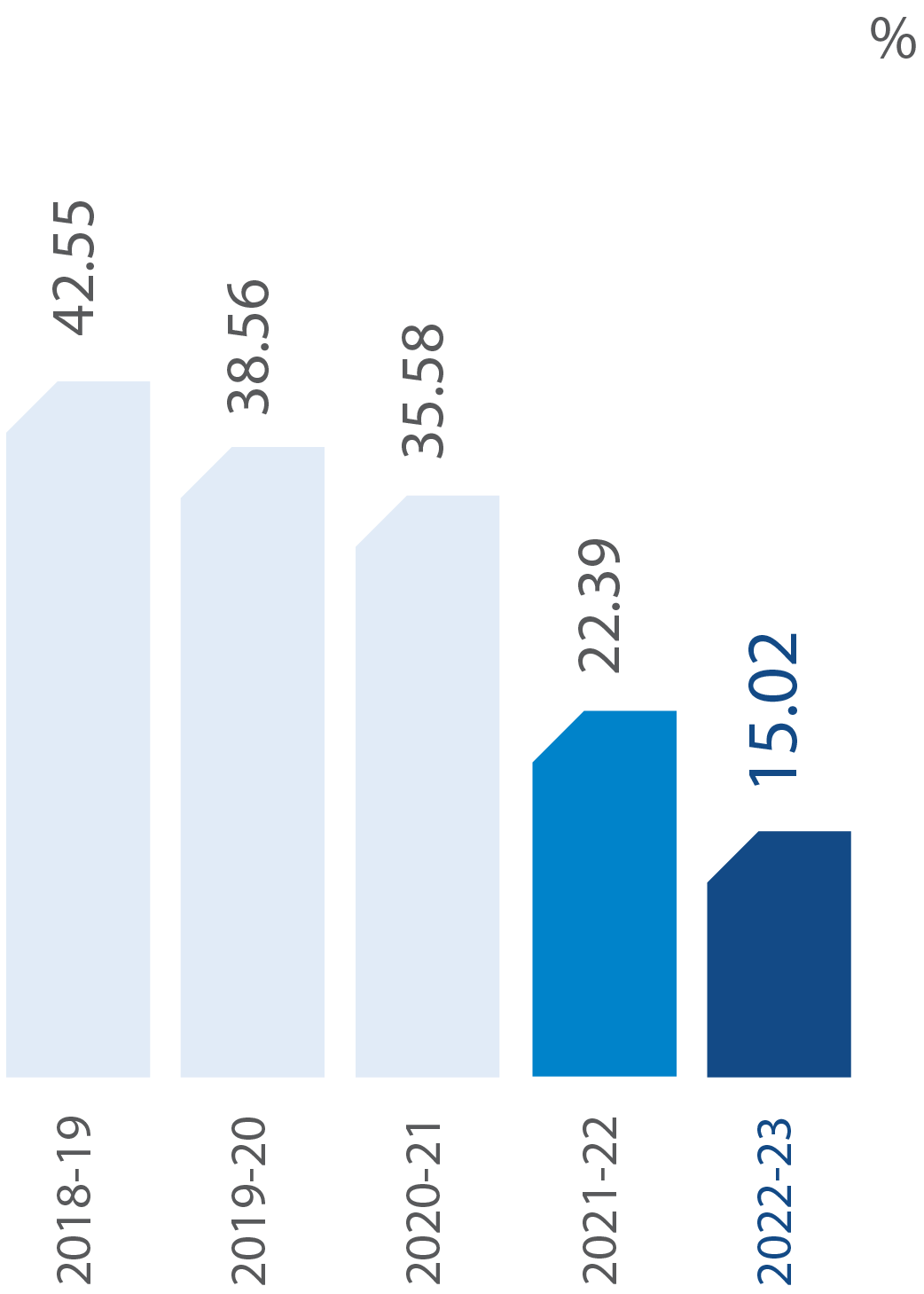

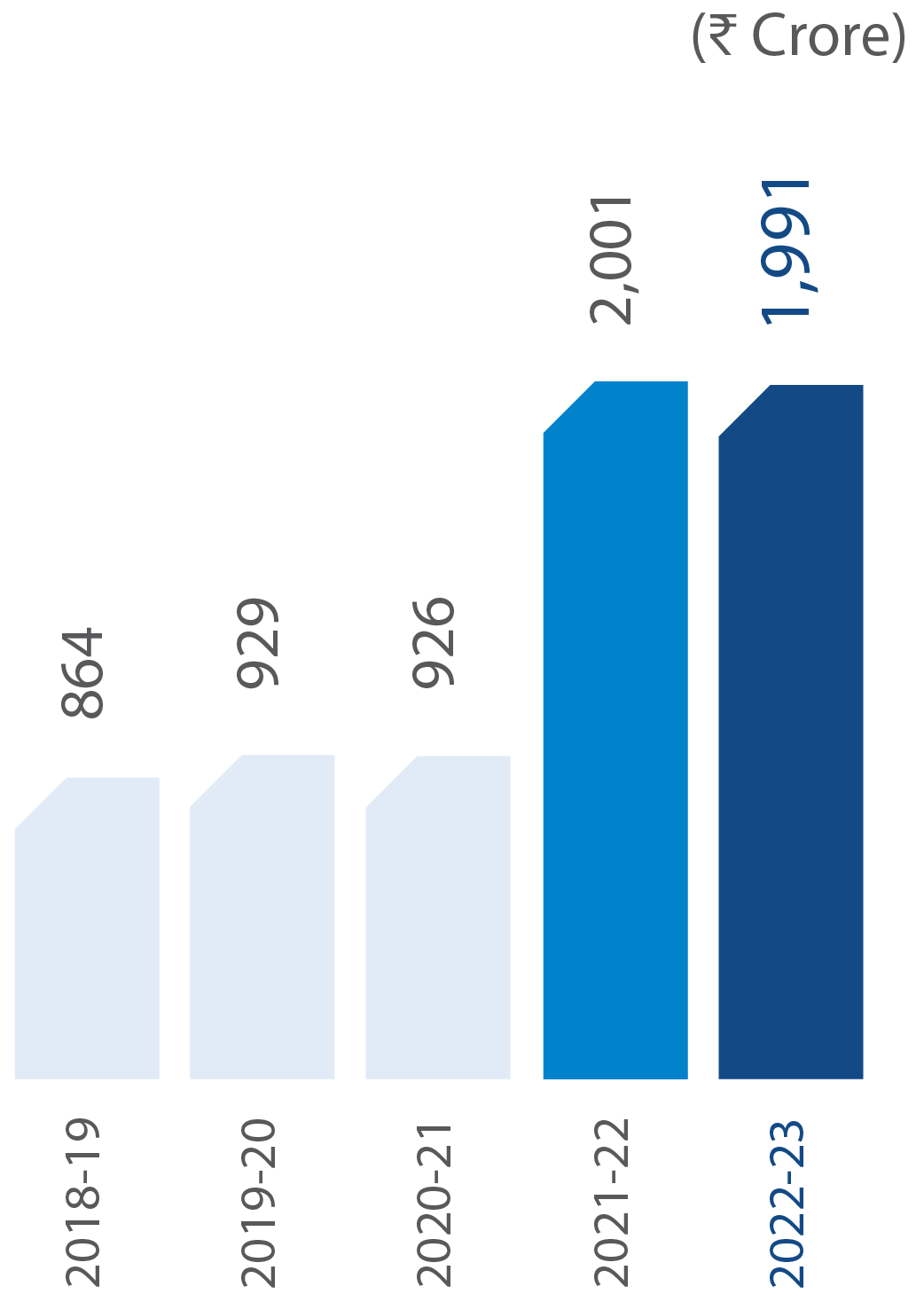

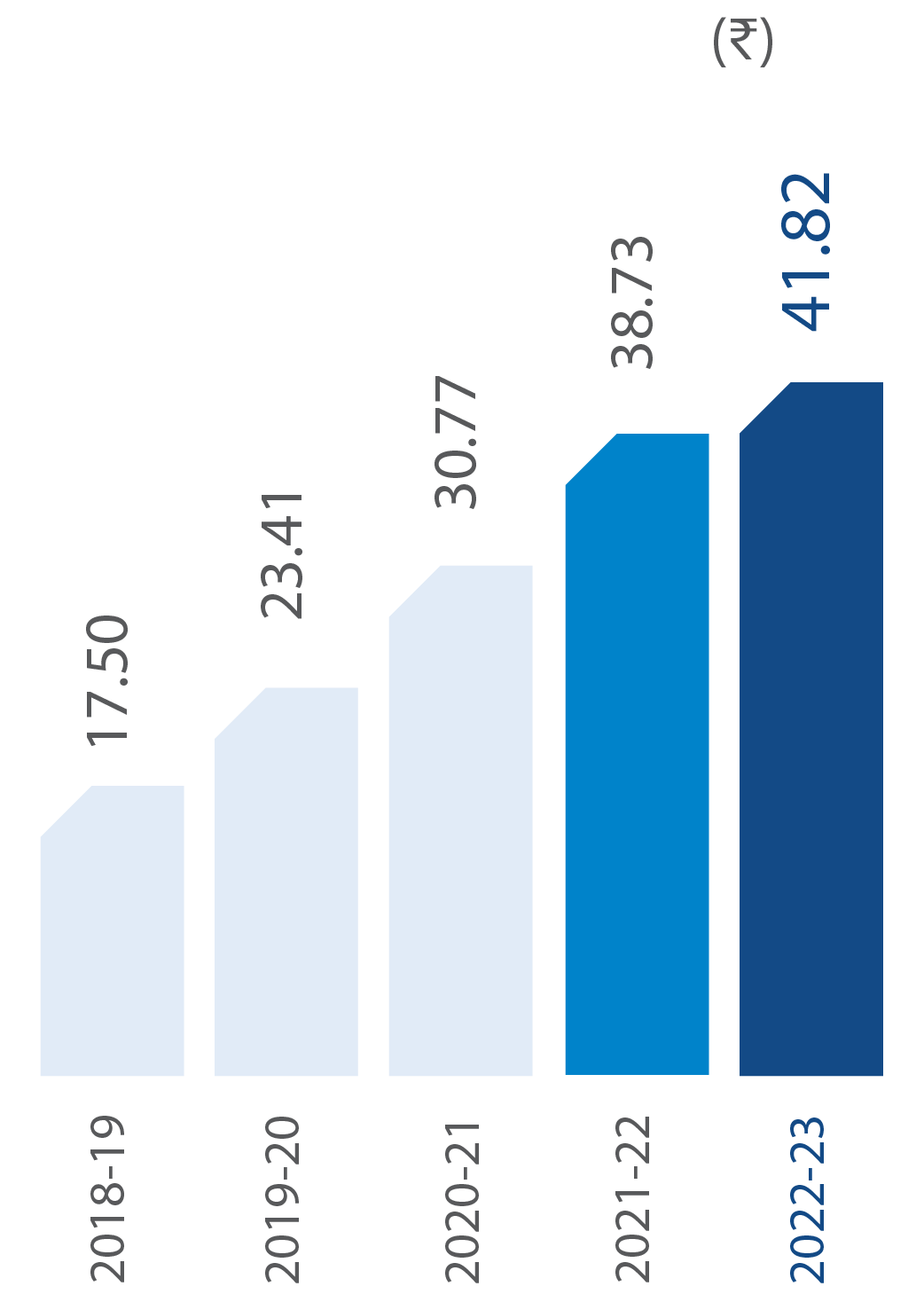

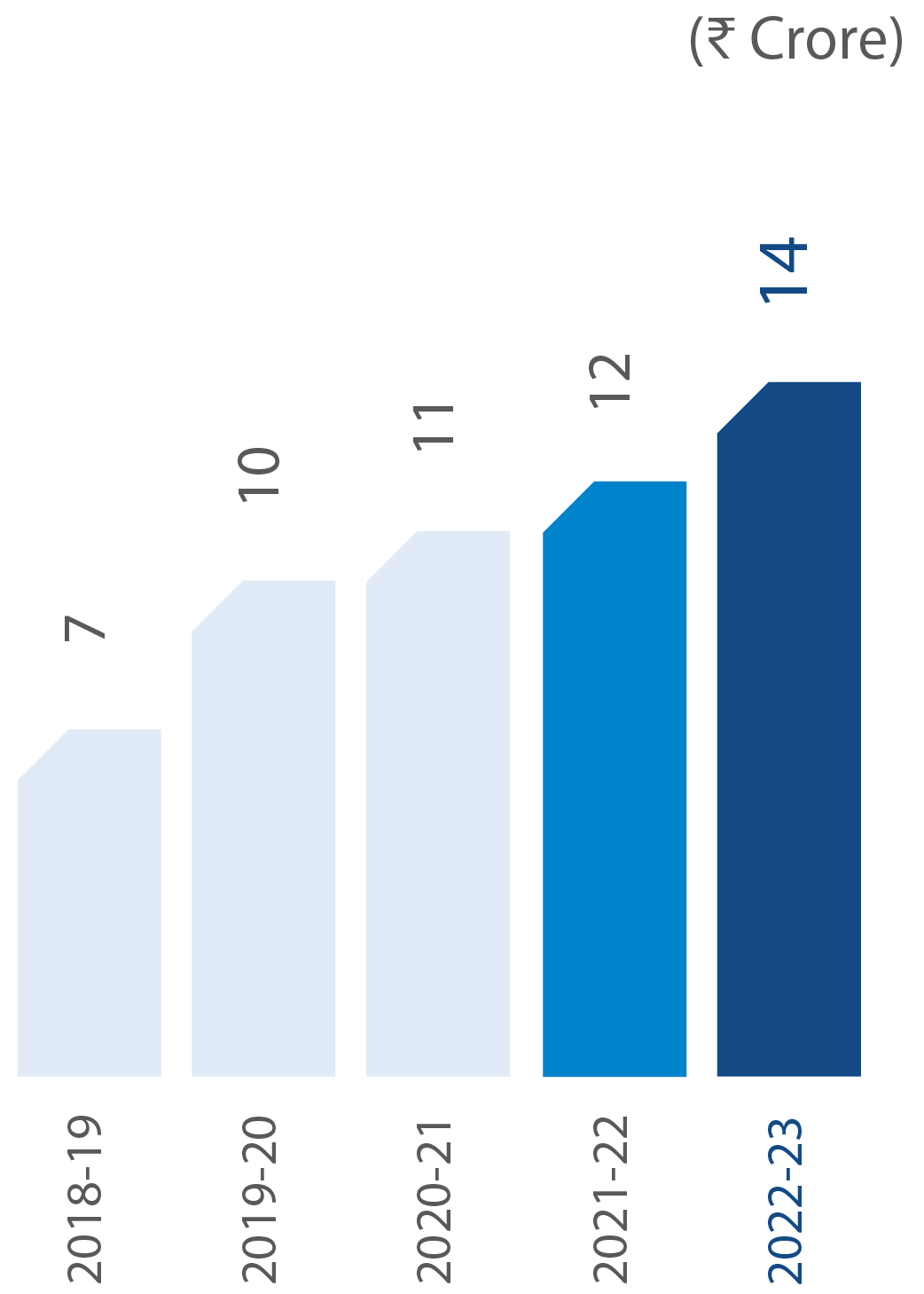

The powerful and aggressive cost improvement programme, ‘Project Unnati’ was launched to identify new cost-saving opportunities. This flagship programme has successfully enabled us to continuously benchmark ourselves against best industry practices and emerging technologies in terms of material and process cost over the last five years. The programme continues to entail cost savings in a variety of areas, resulting in more efficient operations and better-quality assurance. To reduce operational costs, we have implemented several initiatives as a part of this project. The cost-saving programme has helped us secure market competitive product pricing, while mitigating fluctuating commodity costs.

₹248 Crore

Cost saving in F.Y. 2022-23

Download Full Report