Green operations

We made investments in green and sustainable technologies at Crompton this year and intend to continue doing so in the future. In addition to emphasising on the conservation of limited resources and minimising harmful emissions, our strategy also focuses on sustainable management at all stages throughout the value chain and the life-cycle of the products.

We have eliminated plastic and thermocol during packaging as they pose a great danger to landfills.

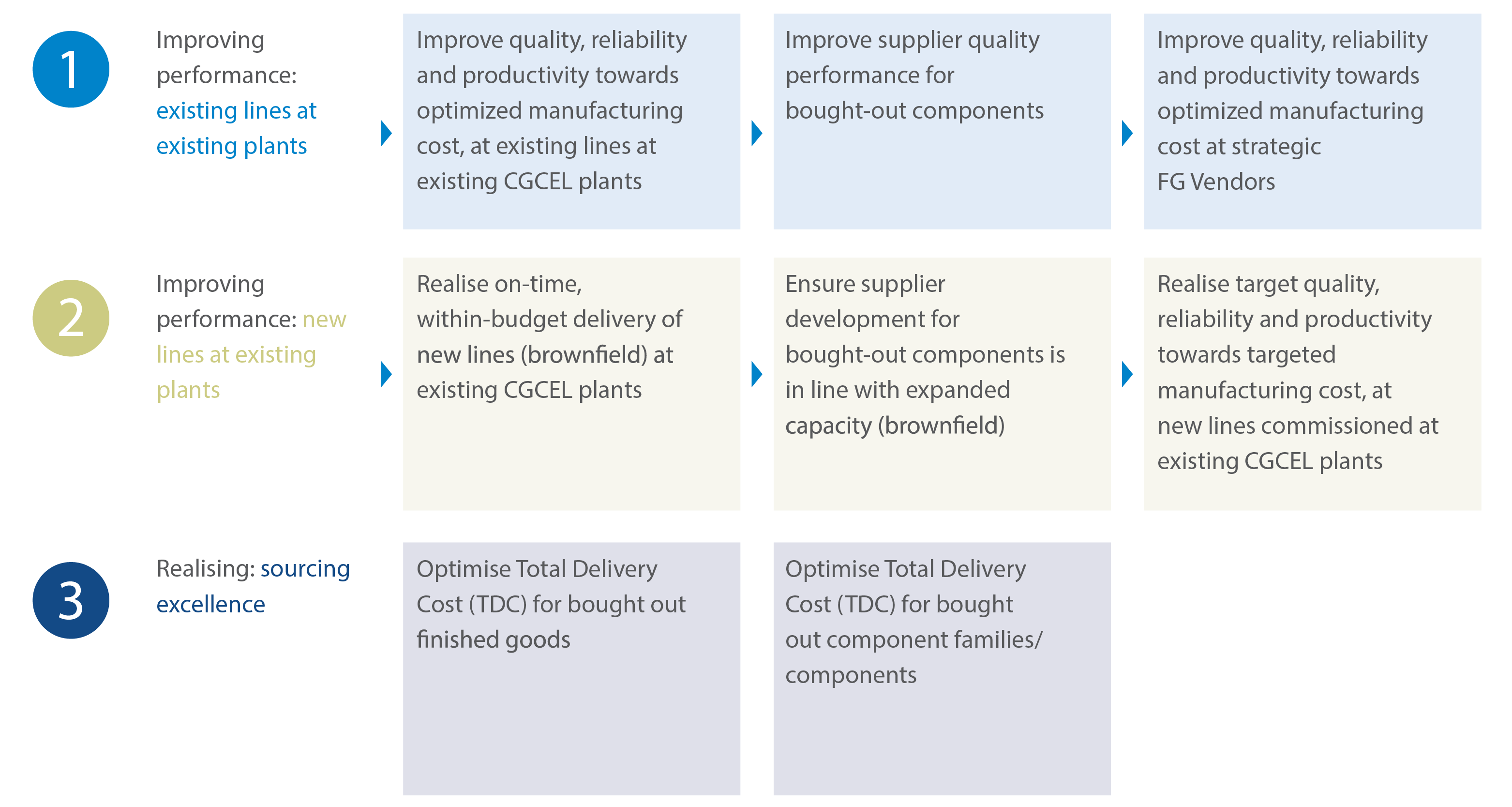

Partnering for excellence

In pursuit of sourcing excellence, we have made significant progress in monitoring vendor performance through the implementation of a vendor scorecard. This scorecard evaluates vendors based on key parameters such as cost, quality and delivery. The Vendor Performance Index (“VPI”) is derived from the vendor scorecard and serves as a crucial metric for assessing vendor performance. We are actively working on improving the VPI score of vendors to achieve a minimum threshold of 75%. To achieve sourcing excellence and maintain strong vendor relationships, we give preference to vendors that score high on the VPI, ensuring effective vendor strategy/ management.

Additionally, we are committed to attaining quality excellence at the vendor's end. External agencies have been engaged to assess vendor performance and action plans have been formulated to enhance internal deliverables such as PPR (Product Performance Review), TBR (Test Bed Rejection) and VQP (Vendor Quality Performance). These internal improvements serve as the foundation for enhancing lead indicators like VPI. We have taken several initiatives to enhance quality, including the release of a quality manual, the implementation of a zero-tolerance policy and the establishment of a Bill of Material validation process.

Moreover, the digitalisation of all vendor data on a dedicated vendor portal has been carried out to facilitate improved quality at the vendor's location. During the BEE (Bureau of Energy Efficiency) transition in fans, we collaborated closely with vendors. The design and quality representation team from Crompton worked alongside the vendor design and quality team throughout the entire production process, from the initial gate to the final productionisation gate. To ensure the delivery of highquality products, we ensure that all critical parts designs are approved by the design team and that procurement of critical parts is exclusively carried out by CGCEL-approved suppliers. Moreover, in a strategic move to reduce dependency on vendors, we have acquired ownership of tools and moulds, thus mitigating potential supply chain risks. These initiatives collectively highlight our commitment to sourcing and quality excellence.

Download Full Report